Printed Circuit Boards (PCBs) function as the fundamental electronic component while choosing proper materials becomes essential to achieve optimal performance combined with durability alongside cost-effectiveness. Different PCB materials possess diverse characteristics including electrical insulation properties together with thermal properties as well as mechanical strength characteristics. FR4 alongside aluminum base and ceramic together with polyimide form the common group of PCB materials that work best for various applications.

1. Factors to Consider When Choosing PCB Materials

To make a correct choice of PCB material you should evaluate the following points:

1.1 Thermal Conductivity

Strong thermally efficient materials are needed for applications with high power requirements.

Metal-based PCBs (e.g., aluminum, copper) offer better thermal management than standard FR4.

1.2 Electrical Performance

The electrical signal transmission speed and integrity depend on dielectric constant (Dk).

To prevent signal loss in high-frequency PCBs one should use materials with a low Dk value.

1.3 Mechanical Strength

The mechanical reliability along with flexibility determine PCB performance when used under dynamic conditions.

Flexible circuits contain polyimide materials rather than rigid PCB boards which normally use FR4 material.

1.4 Cost and Manufacturability

Some production materials require more expense and manufacturing requires additional skills.

The price point of FR4 stands lower than ceramic and metal PCB alternatives that come with a higher cost, get more information.

2. Comparison of Common PCB Materials

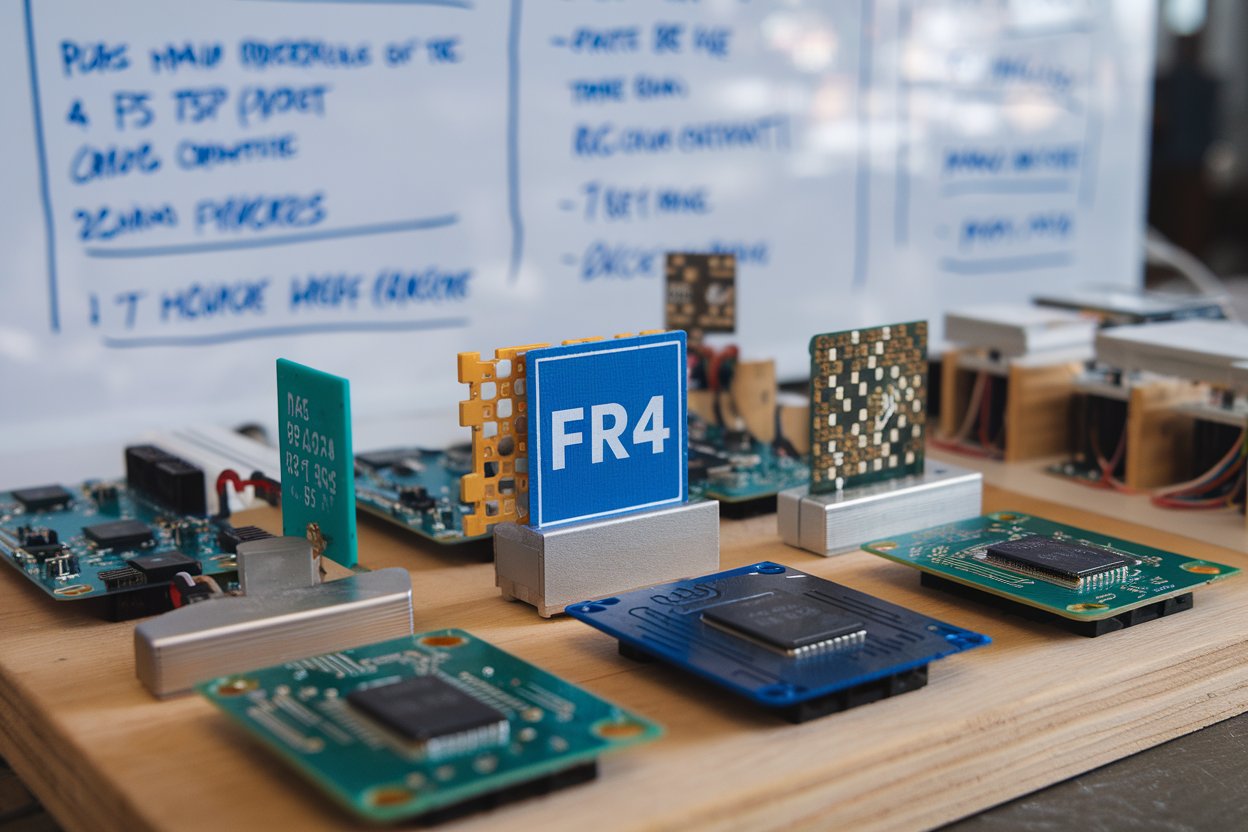

2.1 FR4 (Fiberglass Epoxy Resin)

Overview

FR4 stands as the preferred PCB material because it offers affordable cost alongside durable properties along with excellent electrical insulation properties. The material starts with woven fiberglass but received its protective layer from epoxy resin.

Advantages

✔ Cost-effective and widely available.

✔ Good mechanical strength and electrical insulation.

✔ Suitable for multilayer PCBs.

Disadvantages

This material poses problems with thermal conductivity thereby making it ill-suited for devices that require high power usage.

✖ Not ideal for high-frequency circuits due to signal loss.

Best for:

Consumer electronics (smartphones, laptops, TVs).

Low to medium-power applications.

General-purpose PCBs.

2.2 Aluminum Base PCB

Overview

The thermal properties of aluminum-based PCBs improve through the substitution of metal cores instead of fiberglass components.LED lighting and power electronics industries as well as automotive applications make regular use of this material.

Advantages

Ceramic materials enable better thermal performance which eliminates or lessens the necessity of heat sinks.

✔ Higher durability compared to FR4.

✔ Environmentally friendly and recyclable.

Disadvantages

✖ Higher manufacturing cost than FR4.

✖ Less flexibility for complex multilayer designs.

Best for:

High-power LED circuits.

Automotive and industrial applications.

Power electronics and motor controllers.

2.3 Ceramic PCB

Overview

The thermal and electrical properties of Ceramic PCBs work through alumina (Al₂O₃) and aluminum nitride (AlN) materials. The materials succeed in high-frequency operation together with high-temperature conditions.

Advantages

✔ Extremely high thermal conductivity.

The material offers minimal dielectric losses which suit RF and microwave usage needs.

✔ Resistant to high temperatures and harsh conditions.

Disadvantages

✖ Very expensive.

Mechanical forces could easily cause aluminum oxide and aluminum nitride to break and develop cracks.

Best for:

Aerospace and military electronics.

High-frequency RF applications.

Power semiconductor circuits.

2.4 Polyimide (Flexible PCB Material)

Overview

PCBs made from polyimide provide flexibility together with durability to support wearable technology applications and aerospace systems and medical equipment.

Advantages

✔ Highly flexible, suitable for dynamic applications.

✔ Good heat resistance and chemical stability.

The reduction of weight and size becomes possible when you use this material in compact design solutions.

Disadvantages

✖ More expensive than FR4.

✖ Complex manufacturing process.

Best for:

Flexible and wearable electronics.

Aerospace and medical devices.

High-reliability applications.

Related Topic: XCV Panel Overview & Uses

Conclusion

The selection of suitable PCB materials depends on multispectral analysis of thermal capacity alongside electrical properties and mechanical requirements as well as cost estimations. The most often selected material for PCBs is FR4 yet aluminum proves superior for heat management whereas ceramic suits high-frequency applications while polyimide functions best for flexible circuits. The selection of your ideal PCB material becomes possible when you understand their individual characteristics.

Sign up for our Daily newsletter

We'll be in your inbox every morning Monday-Saturday with all the day’s top business news, inspiring stories, best advice and reporting from Entrepreneur,